Home > Projects > Mining and Steel Equipment > Conveyor Belt Condition Monitoring System

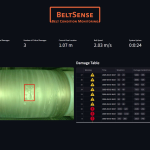

Conveyor Belt Condition Monitoring System (BeltSense)

Belt continuous condition monitoring system can prevent accidents and unpredictable stops. The long length of conveyor belts and the lack of access not only increases the complexity of maintenance, but also causes high financial losses as a result of possible failure.

This system scans the belt surface continuously and warns the user in early stages of development of a damage.

The device features are:

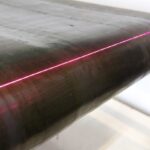

– Belt surface laser scanning

– Detecting cracks and surface damage and measuring their depth

– Monitoring the condition of splices and connections

– Monitoring surface wear and belt thickness

– Measuring belt slip

– Sensing belt misalignment at equipment installation position

– Anticipating downtime and suggesting appropriate maintenance shut down time

– User interface for checking system current state, monitoring failures progress, acknowledging or rejecting them

– Temperature and belt vibration monitoring to predict drums failure

– Monitoring belts with a maximum width of one meter and a maximum speed of two meters per second (these values can be changed according to the order)

Installed Project

Tehran Province, Iran- 2023